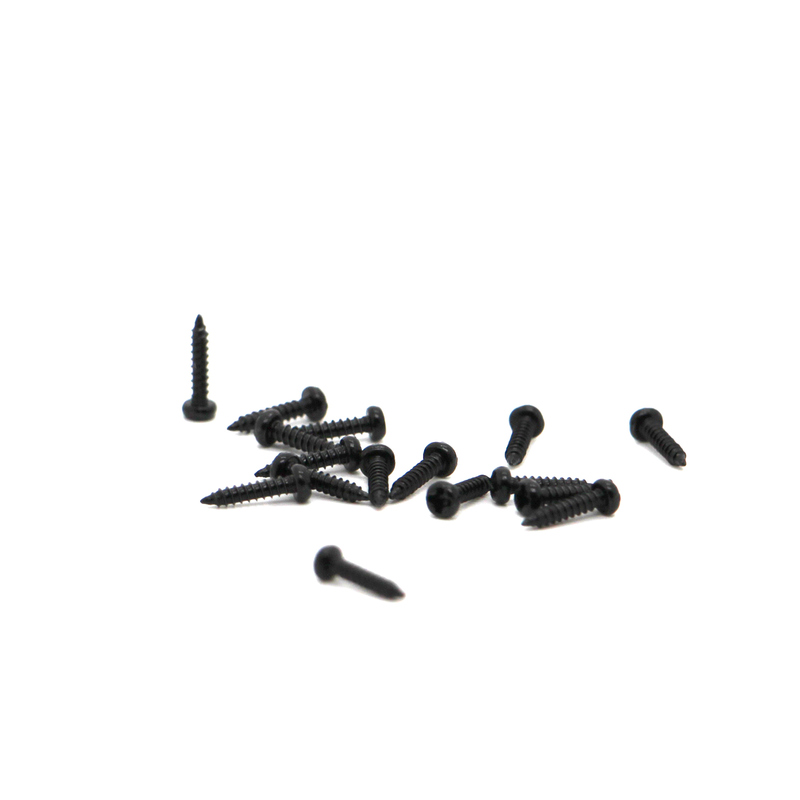

Małe śruby Micro Mini Bolt dla elektroniki

Specjalizujemy się w badaniach, opracowywaniu i produkcji mikro śrub precyzyjnych M0.5-M3.0, o najmniejszej średnicy M0.5 i najkrótszej długości L0.85Dostępne materiały to stal węglowa, stal nierdzewna i tytan, z różnymi rodzajami głowicy (K, P, C) i rodzajami nitki (nitki maszynowe A, B).

Konwencjonalna seria śrub

Sforsowanie ze stali nierdzewnej.

Wyroby z serii sześciokątnej

Wyprodukowany z wysokiej jakości stali nierdzewnej, zapewnia trwałość, odporność na korozję i nierost.

Cechy orzecha nitkowego

- Konstrukcja płyty z powrotem z całkowitym spłukiwaniem

- Kompaktowy rozmiar idealny dla precyzyjnych produktów elektronicznych/elektrycznych

- Wysoka odporność momentu obrotowego

- Kompleksowe serii specyfikacji dla różnych wymagań projektowych

Zagraniczne produkty NC

- Konstrukcja płyty z powrotem z całkowitym spłukiwaniem

- Kompaktowy rozmiar idealny dla precyzyjnych produktów elektronicznych/elektrycznych

- Wysoka odporność momentu obrotowego

- Kompleksowe serii specyfikacji dla różnych wymagań projektowych

Zdolności produkcyjne

Obecnie obsługujemy prawie 100 klientów w branży wyświetlaczy LED i wielu sektorach, w tym systemy wyświetlania komputerów i LED, komunikację mobilną, urządzenia noszone,okulary/zegarek/instrumentyNasze specjalistyczne działy obejmują:

- Duże oddzielenie śrub

- Standardowy podział śruby

- Automatyczne podziały obrabiarek

- Dział obróbki CNC

- Wydział części niestandardowych z wielostacji

Kontrola jakości

Nasz profesjonalny zespół badawczy przeprowadza kompleksowe kontrole, w tym pomiar długości, precyzyjną koordynację, analizę składu chemicznego, właściwości fizycznych,i oceny grubości powłoki.

Wyposażenie do badań

Mikroskop, urządzenie do montażu próbek metalograficznych, pomiar koncentryczności średnicy wewnętrznej i zewnętrznej, eksperyment z parafiną itp.

Sprawdzanie umiejętności

Analiza spektrograficzna, badania mikrohardności, śledzenie konturów, testy solnymi i wiele więcej.

Opakowanie i dostawa

Częste pytania

P: Na jakie rodzaje śrub i elementów mocujących specjalizujesz się?

Odp.: Koncentrujemy się na produkcji precyzyjnych mikroskrutów (M0.5-M3.0) i powiązanych elementów mocujących, w tym niestandardowych, niestandardowo ukształtowanych śrub, funkcjonalnych / składnikowych śrub, orzechów, nitów,i części sprzętowe do pieczętowania/przetworzeniaNasze produkty są szeroko stosowane w elektronikach, inteligentnych urządzeniach do noszenia, urządzeniach medycznych, przestrzeni kosmicznej i innych.

P: Czy można wyprodukować specjalnie zaprojektowane śruby lub elementy mocujące do konkretnych zastosowań?

Odpowiedź: Tak! Doskonale wykonujemy badania i rozwój oraz produkujemy niestandardowe, skomplikowane śruby i funkcjonalne elementy mocujące.Nasi inżynierowie będą współpracować z Państwem, aby spełnić wyjątkowe wymagania dla przemysłu, takich jak urządzenia medyczne., lotnictwa kosmicznego lub elektroniki precyzyjnej.

P: Jaka jest minimalna ilość zamówienia (MOQ)?

O: Oferujemy elastyczne MOQ, wspierając zarówno prototypy małych partii (do badań i rozwoju), jak i produkcję na dużą skalę.

P: Jaki jest typowy czas realizacji zamówień hurtowych?

Odpowiedź: Standardowe zamówienia trwają 25-35 dni (w zależności od złożoności).

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!