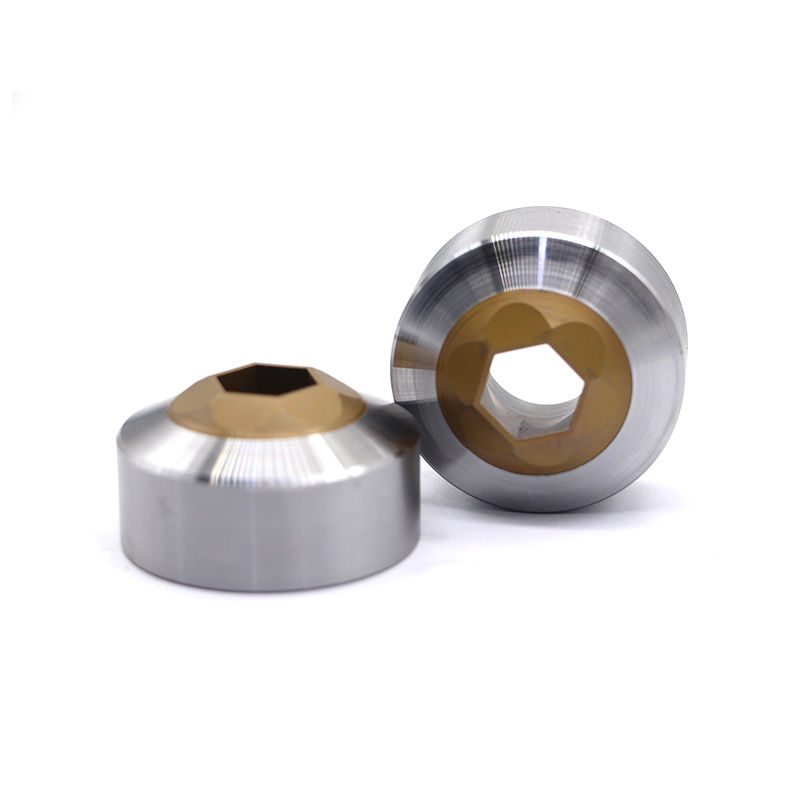

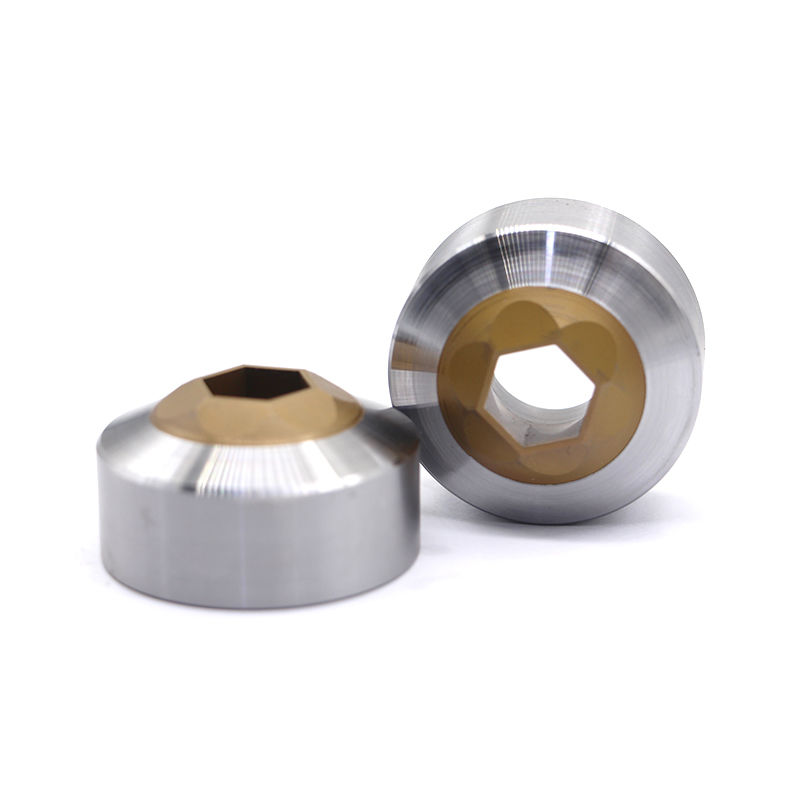

Profesjonalna, dostosowana matryca do przycinania z powłoką CVD z węglika

Specyfikacje produktu

| Tryb formowania |

Forma do wytłaczania |

| Materiał produktu |

Węglik |

| Nazwa produktu |

Matryca do przycinania |

| Zastosowanie |

Forma do produktów gospodarstwa domowego |

| Obróbka powierzchniowa |

Powłoka |

| Rozmiar |

Rozmiar dostosowany |

| Żywotność formy |

250000-300000 strzałów |

| Użycie |

Pole przemysłowe |

| MOQ |

10 |

| Pakowanie |

Karton |

Przegląd produktu

Kluczowe zalety

- Porady ekspertów dotyczące gatunków węglików i stali dla różnych zastosowań

- Idealny promień styczny dla precyzyjnego przycinania

- Obróbka mechaniczna powierzchni, gdzie jest to geometrycznie możliwe

- Szeroki zakres kształtów o wysokiej złożoności geometrycznej

- Optymalny dobór powłoki dla ciętych materiałów

- Polerowanie lustrzane przed i po nałożeniu powłoki

- Tolerancje ±0,005 mm

- Konkurencyjne ceny dla jakości przemysłowej

Specyfikacje materiałowe

Główne materiały obudowy: M2, M42

Skład M42 (SKH59)

| C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

W |

| 1.06% |

0.3% |

0.31% |

0.018% |

0.002% |

3.74% |

9.29% |

1.1% |

1.34% |

| Cu |

Ni |

Co |

|

| 0.07% |

0.29% |

7.97% |

|

Skład M2 (H9)

| C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

W |

| 0.85% |

0.33% |

0.34% |

0.027% |

0.005% |

4.12% |

4.73% |

1.78% |

5.74% |

| Cu |

Ni |

|

| 0.12% |

0.24% |

|

Obróbka powierzchniowa

Powłoka PVC dla zwiększonej trwałości

Możliwości produkcyjne

Chongqing Henghui Precision Mold Co., Ltd. działa z zaawansowanym sprzętem CNC, w tym tokarkami, centrami obróbczymi, szlifierkami do wałków, maszynami EDM i maszynami do cięcia. Nasza kontrola jakości obejmuje testery twardości Rockwella, projektory i przyrządy do pomiaru obrazu 3D.

Specjalizujemy się w wysokiej jakości materiałach z węglika wolframu z profesjonalną obróbką cieplną próżniową, dostarczając precyzyjne formy dla przemysłu kucia na zimno i na gorąco z dokładnością wymiarową w granicach 0,005 mm i współosiowością w granicach 0,01 mm.

Działając w ramach systemu zarządzania jakością ISO9001:2015, obsługujemy rynki globalne, w tym Azję Południowo-Wschodnią, Europę i Stany Zjednoczone, stosując podejście zorientowane na klienta.

Pakowanie i dostawa

Pakowanie: Pudełko kartonowe; Pakiet eksportowy standardowy lub zgodnie z wymaganiami klienta.

Dostawa: 12-45 dni w zależności od ilości zamówienia.

Często zadawane pytania

P1: Jak mogę otrzymać wycenę?

O1: Skontaktuj się z nami z rysunkami, specyfikacjami materiałowymi, ilością i wymaganiami dotyczącymi obróbki powierzchni w celu szybkiej wyceny.

P2: Jaki jest Twój czas realizacji?

O2: Czas realizacji zależy od ilości zamówienia i kraju przeznaczenia.

P3: Jakie jest Twoje minimalne zamówienie?

O3: MOQ różni się w zależności od produktu - skontaktuj się z naszym zespołem sprzedaży, aby uzyskać szczegółowe informacje.

P4: Jakie metody płatności akceptujecie?

O4: Akceptujemy T/T, L/C i PayPal.

P5: Jaką obsługę posprzedażną świadczycie?

O5: Kompleksowe wsparcie, w tym pomoc techniczną, naprawy i wymiany.

P6: Jak mogę otrzymać katalog produktów?

O6: Skontaktuj się z naszym zespołem sprzedaży za pośrednictwem strony internetowej lub poczty elektronicznej, aby uzyskać katalog i wycenę.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!